Forget carbon fiber—we can now make carbon nanotube fibers

Ars Technica » Scientific Method 2018-05-15

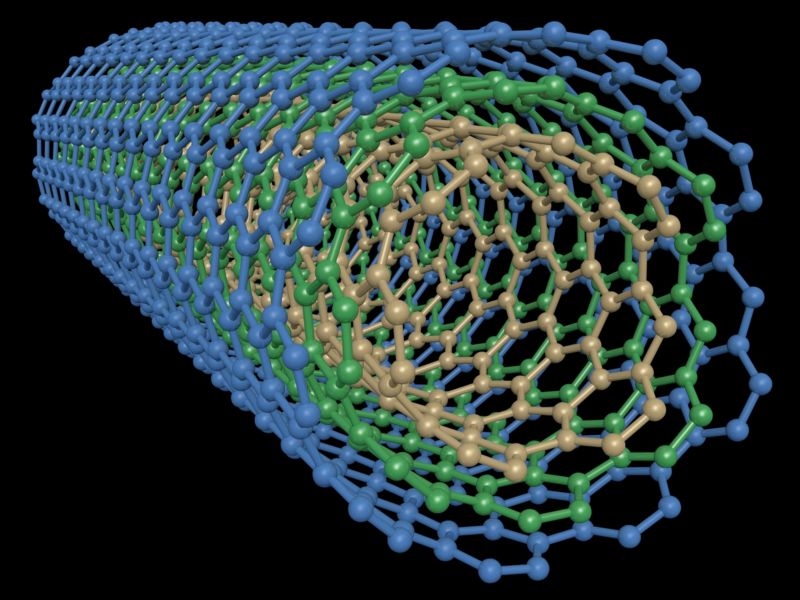

Enlarge / A multi-walled carbon nanotube. (credit: NASA)

A carbon nanotube is tough—by some measures, more than 30 times more robust than Kevlar. As they're only a few atoms thick, however, that toughness isn't especially useful. Attempts have been made to bundle them together, but nothing has worked out especially well; the individual nanotubes are typically short, and it's difficult to get them to all line up in the same direction. As a result, these attempts have resulted in bundles that are filled with structural defects, often perform worse than Kevlar, and are only a few micrometers long.

Now, a group at Beijing's Tsinghua University seems to have found a way around many of these problems. It was able to synthesize nanotubes that are centimeters long and bundle them together to make a fiber that's nearly as strong as an individual nanotube. It's not quite time to start booking rides on a space elevator, but this work at least hints that nanotubes might eventually break out of the realm of the microscopic.

Go long

The biggest problem with assembling nanotubes into a useful fiber is the length of the individual nanotubes. It's what keeps the fibers short, and the loose ends probably contribute to the defects that weaken the end product. So the first step in building better ones was finding a way to make longer carbon nanotubes in the first place. This was accomplished through a variant of a standard technique called chemical vapor deposition, in which the reactants that generate the nanotube are present in the atmosphere of the reaction chamber. In this case, the researchers flow the reactants through the chamber in a single direction, and the nanotubes grow along the same direction as that flow.